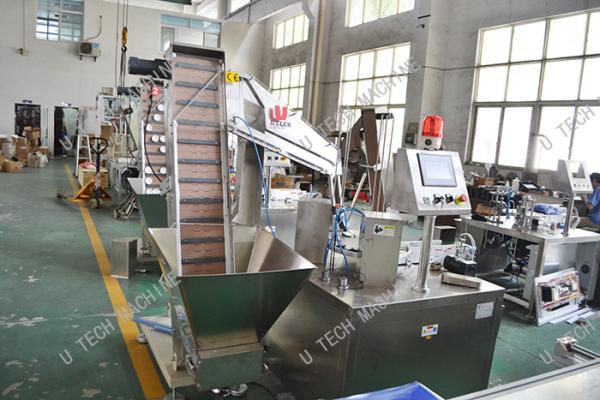

Automatic caps lining machine cap wadder inserting machine cosmetic

bottle caps liner system

Designed and manufactured by U TECH cosmetic&food&pharma

making and packaging machinery is widely used in the daily chemical

industry like the caps wadding lining system and such like.We

moreover can design and produce the packaging machine according to

the special requirements from customers.

We offer you high quality designed machines than can cut & place

liner in different caps' sizes by simply interchanging tooling and

die-set. Easy access to the die-set allows operators to achieve

fast changeovers and facilitates maintenance. Our new generation of

punch and die-ring can now be resharpened without removing the

complete die-set from the machine.

The movement of the push pad is driven by a cam and the timing can

be changed according to the type of liner material. The servo motor

assures a precise movement of the liner material in order to have a

perfect cut according to the caps' diameter.

Our top plate is nickel plated to avoid rust without affecting

precision. The covers of the material unwinder and scrap rewinder

are of stainless steel for maximum durability.

PLC control by mitsubshi,touch screen is HIM,bad product will

automatic remove,automatic count,automatic alarm and stop

1) substitution of handicraft,the gaskets go into a bottle of cover

automatically

2) pressurizing gaskets completely

reasonably,quickly,efficiently,and the safe and hygiene products

3) suiting the usage situation which requests the hygiene condition

specially,avoiding second pollution to the material,economizing a

disinfectant craft

4) transporting the covers and accurate orientation system

5) neatening the cover organization can get rid of waster ,and all

covers head up

6) the whole machine adopts PLC controls,reports to the police

without the bottle cover or gaskets

7) having autocount function,chooseing the suit gaskets to

cover,getting rid of waster having no gaskets inside after filling

gaskets into the cover

8) The whole machine efficiency is higher,if the diameter 30~50 mm

cover,the speed is 60covers or so per minute

Technique Parameter

model | BST-1200 |

Speed | Max 120 caps/min |

Electricity power | 380V, 50HZ |

power | 2000W |

Air compression | 30L/min, ≥0.4Mp |

host equipment size | 1100mm*900mm*1400mm |

Cap elevator and cap feeding device | 1700mm*750mm*1200mm |

Foil sending device | 500mm*500mm*750mm |

Waster soil sending device | 500mm*500mm*650mm |

conveyor | 1200mm*100mm*200mm |

Machine weight | 1100Kg |

The certificate